MIL-DTL-82909A (OS)

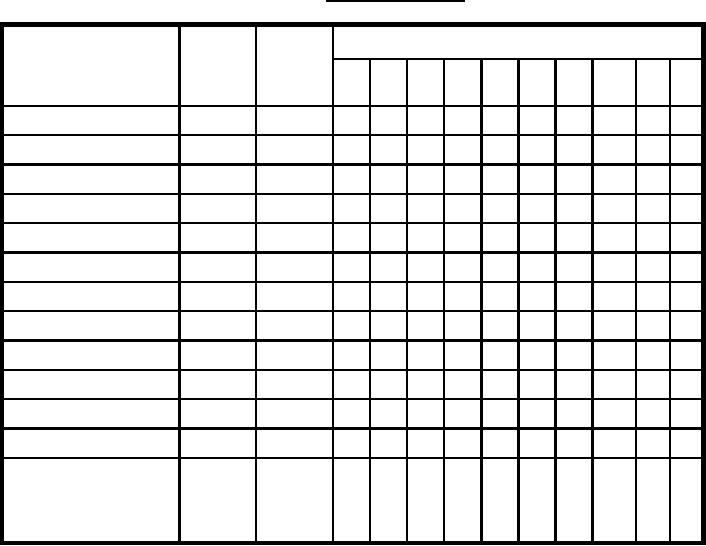

TABLE III. First article test plan.

Test

Req.

Sample Group

Test Sequence

Para.

Para.

I

II

III

IV

V

VI

VI

VIII

I

X

I

X

1. Visual

4.3.1

3.5.1, 3.7

6

3

3

3

3

3

3

3

3

3

2. Radiographic

4.3.2

3.5.2

6

3

3

3

3

3

3

3

3

3

3. Leakage

4.3.3

3.5.3

6

3

3

3

3

3

3

3

3

3

4. Insul. Resistance

4.3.5

3.5.5

6

3

3

3

3

3

3

3

3

3

5. Dielectric

4.3.6

3.5.6

6

3

3

3

3

3

3

3

3

3

6. Vibration1, 2

4.3.7

3.6.1

6

7. Shock1

4.3.8

3.6.2

3

8. TSHA1

4.3.9

3.6.3

3

9. Saltfog1

4.3.10

3.6.4

3

10. Six-Foot Drop1

4.3.11

3.6.5

3

11. Forty-Foot Drop

4.3.12

3.6.6

3

12. Firing Mechanism

4.3.13

3.6.7

3

13. Function test:

4.3.14

3.6.8

-65 ± 5°F

22

11

11

11

11

11

3

70 ± 5°F

2

1

1

1

1

1

3

200 ± 5°F

3

1

A visual, radiographic, insulation resistance, dielectric measurement inspections shall be conducted

following the specific test.

2

Footnote 1 shall be conducted after the Non-Gunfire and the Gunfire Vibration test.

4.2.3.1 Sample size. A random sample of battery packs from each production lot, including the samples

retained for investigative purposes, shall be selected in accordance with table V for lot acceptance

inspection. Test sample battery packs and samples retained for investigative purposes shall not be applied

as part of the quantity specified for delivery by the contract or purchase order.

4.3 Inspections and tests.

4.3.1 Visual inspections.

4.3.1.1 Battery pack inspection. The external condition and appearance of the battery packs shall be

determined by comparison to Drawing MBEU147990. Specific inspections of the electrical connector,

stainless steel battery case, aluminum manifold, and identification label shall be conducted at a minimum.

Each battery pack shall meet the requirements of 3.5.1 and 3.7.

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business