MIL-DTL-82909A (OS)

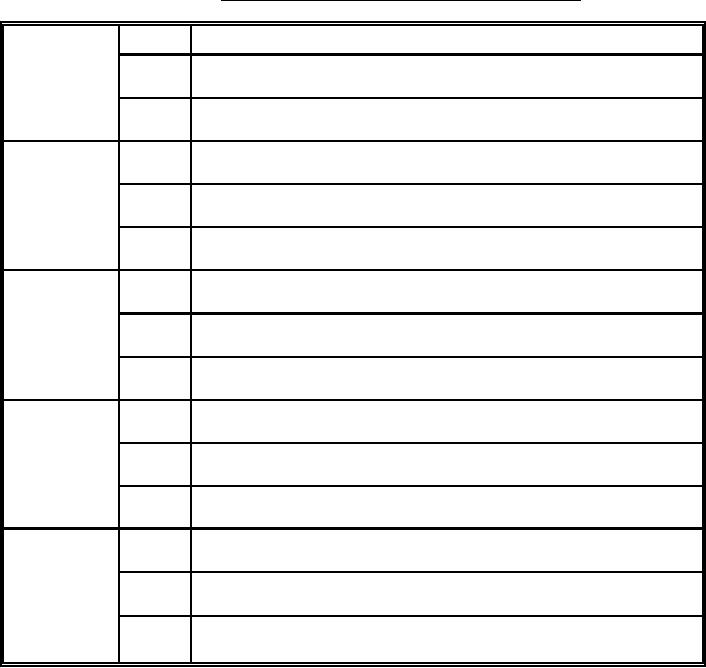

TABLE VIII. Temperature shock/humidity/altitude cycling schedule.

Place battery packs in a chamber at 70°F at 50% relative humidity (RH).

800

Raise chamber temperature to 160°F and the RH to 95%. The chamber temperature shall

reach 160°F at 95% RH no later than 1300.

1200

Remove battery packs from chamber and immediately place in chamber maintained at

-65°F at a pressure altitude of 70,000 feet - (0.65 psi)

Monday

1600

Remove battery packs from chamber and immediately place in chamber maintained at

70°F at 50% RH.

800

Remove battery packs from chamber and immediately place in chamber maintained at

-65°F at a pressure altitude of 70,000 feet - (0.65 psi)

1200

Remove battery pack from chamber and immediately place in a chamber maintained at

160°F at 95% RH.

Tuesday

1600

Reduce chamber temperature to 70°F and RH to 50%. The chamber temperature shall

reach 70°F at 50% RH no later than 0900.

800

Raise chamber temperature to 160°F and RH to 95%. The chamber temperature shall

reach 160°F at 95% RH no later than 1300.

1200

Remove battery packs from chamber and immediately place in chamber maintained at

-65°F at a pressure altitude of 70,000 feet - (0.65 psi)

Wednesday

1600

Remove battery packs from chamber and immediately place in chamber maintained at

70°F at 50% RH.

800

Remove battery packs from chamber and immediately place in chamber maintained at

-65°F at a pressure altitude of 70,000 feet - (0.65 psi)

1200

Remove battery pack from chamber and immediately place in a chamber maintained at

160°F at 95% RH.

Thursday

1600

Reduce chamber temperature to 70°F and RH to 50%. The chamber temperature shall

reach 70°F at 50% RH no later than 0900.

800

Raise chamber temperature to 160°F and RH to 95%. The chamber temperature shall

reach 160°F at 95% RH no later than 1300.

1200

Remove battery pack from chamber and immediately place in a chamber maintained at

-65°F at standard ambient pressure.

1600

Friday

This schedule shall be followed for a total of four (4) weeks (28 days) except that on the second and

fourth weekend the soak time shall be from 1200 on Friday until 0800 Monday at a temperature of 160°F

at 95 percent relative humidity.

4.3.10 Salt fog test. The battery packs, with protective plugs installed in the inlet and electrical ports,

shall be submitted to the salt fog test outlined in MIL-STD-810, method 509 with the following

requirements:

a. Waxed string shall be used to support the battery packs in the chamber. The battery pack shall be

oriented in the manifold up position as shown in figure 1. No change in orientation is required during the

test. The battery packs shall be exposed to a 5 percent salt solution for 168 hours. Condensed fog shall be

17

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business