MIL-DTL-82909A (OS)

3.5.3 Leakage. The leakage rate of each thermal battery, prior to being installed into the battery pack

manifold, shall not exceed 1.0 x 10-5 cc/sec of air when tested in accordance with 4.3.3.

3.5.4 Polarity. Each thermal battery in the battery pack shall have a polarity that matches the power and

starter stack positive and negative lead configuration when tested in accordance with 4.3.4.

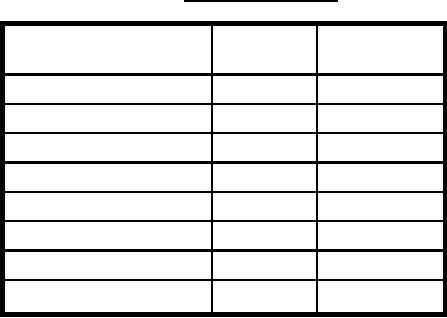

TABLE I. Production inspections.

Test Sequence

Test

Requirement

Paragraph

Paragraph

1. Visual

4.3.1

3.5.1, 3.7

2. Radiographic Inspection

4.3.2

3.5.2

3. Leakage

4.3.3

3.5.3

4. Polarity

4.3.4

3.5.4

5. Insulation Resistance

4.3.5

3.5.5

6. Dielectric Measurement

4.3.6

3.5.6

7. Firing Pin

-

3.5.7

8. Actuation

4.3.13

3.5.8

3.5.5 Insulation resistance. Each battery in the battery pack shall have a resistance greater than 1

megohm between the leads to case and between each set of output leads when tested in accordance with

4.3.5.

3.5.6 Dielectric measurement. Each battery in the battery pack shall not have a current drain exceeding

0.1 milliampere for a 60-second period between the leads to case and between each set of output leads

when tested in accordance with 4.3.6.

3.5.7 Firing pin. Each firing pin shall have free movement (without O-ring installed) and proper

alignment and protrusion in the manifold. This shall be verified during assembly of each firing pin in the

manifold.

3.5.8 Actuation. The number of firing mechanisms selected from the manifold assembly production lot

for the test shall be in accordance with table V. The retained sample shall be ignored. The mechanism shall

shear between 400 to 650 psig when subjected to an onset rate of 20,000 to 40,000 psig/sec of air pressure

to the inlet port when tested in accordance with 4.3.13. Failure to meet this requirement shall cause

rejection of the lot. Any mechanism subjected to this test shall be discarded or certified acceptable by

quality assurance before it is reworked for use.

3.6 Battery pack performance. Battery packs shall meet all requirements of 3.6.1 through 3.6.8 and the

acceptance criteria of 4.4.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business