MIL-B-18F

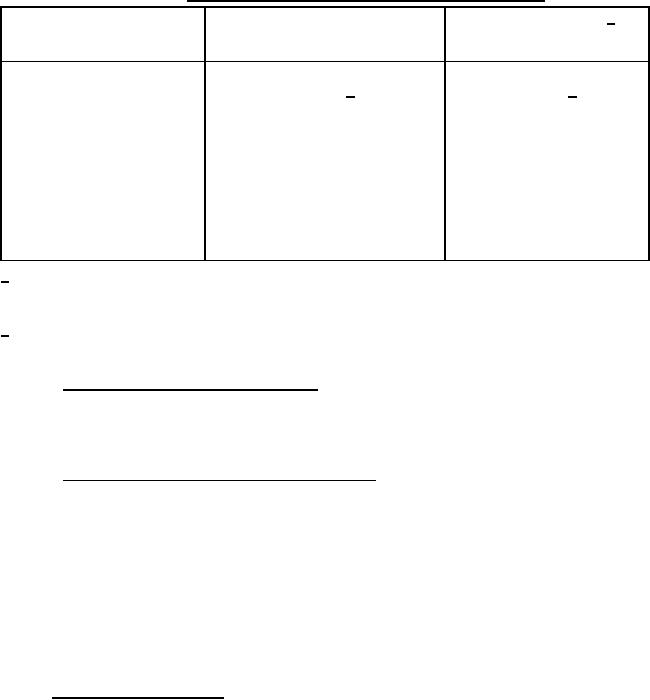

TABLE VIII. Sample size and acceptance number for each capacity test.

Acceptance number 1/

Contract lot

Sample size "n" for

size "N"

each capacity test from

T and D tests

contract lot

0 to

110

5 2/

--- 2/

111 to

500

15

3

501 to

800

25

5

801 to 1,300

35

7

1,301 to 3,200

50

9

3,201 to 8,000

75

13

8,001 to 22,000

110

18

22,001 to 110,000

150

24

over 110,000

225

34

1/ When the number of capacity values, falling below the minimum requirements specified (see 3.1) for a

given test, is equal to or less than the associated acceptance number, the contract lot from which the

sample was drawn has met the requirements of that test.

2/ Determination of compliance, specified in 4.6.1.4.2, shall not apply to contract lot-sizes less than 111.

4.6.1.4.1.1 Smaller-than-shipment (sub-shipment) lots. At the option of the contractor, selection of sample

batteries (see 4.6.1.4.1) may be made on a smaller-than shipment (sub-shipment) lot basis. In such case, the sample

size for the sub-shipment lot shall bear the same ratio to the sample size for the shipment lot as the sub-shipment lot

bears to the shipment lot.

4.6.1.4.1.2 Allocation of sample batteries for group C inspection. The number of batteries ns, selected from a

shipment lot (see 4.6.1.4.1), shall be assigned at random for group C inspection as follows:

The quantity of batteries ns in the sample of the first shipment lot shall be selected at random and assigned to

a.

the capacity tests. The first battery shall be assigned to the T test, and the second one to the D test. This

sequence of assignment of sample batteries to the two capacity tests shall be resumed in each succeeding

shipment lot at the same point at which it ended in the previous shipment lot.

b.

The assignment of batteries to capacity tests shall result in the allocation of exactly n batteries to each of the

two capacity tests after the final shipment on the contract lot is made. If necessary, the sample size ns taken

from the last shipment lot of a contract lot shall be adjusted so that this result is achieved.

4.6.1.4.2 Determination of compliance. The entire contract lot shall be considered as complying, when the T test

results show compliance. To determine whether the contract lot conforms to the specified T test requirements, the

number of batteries in the sample with capacity values below the minimum capacity value (SLT) specified in 3.1, shall

be compared with the acceptance numbers for sample sizes n in table VIII. When the number for a given test is less

than or equal to the corresponding acceptance number, the contract lot complies with the requirements of the test.

When the number is greater than the acceptance number, the contract lot does not comply.

23

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business