MIL-B-18F

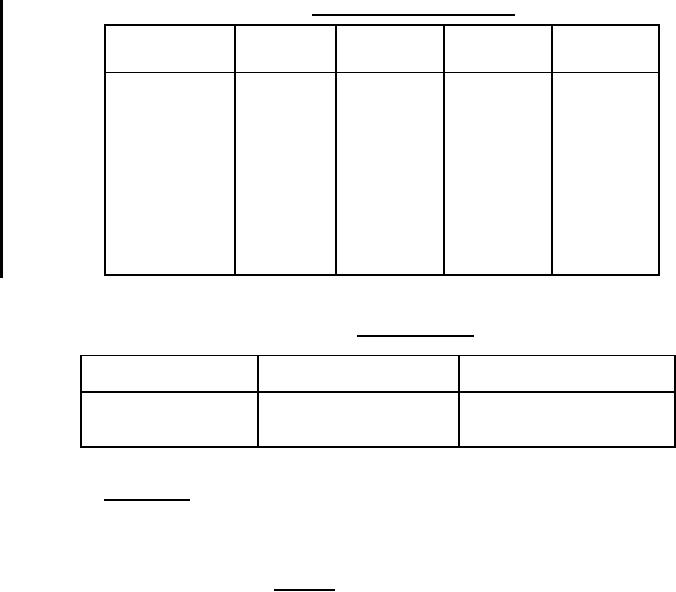

TABLE VI. Group B inspection sampling plan.

Lot size

Sample

Sample

Sample

Sample size

size A

size B

size C

D

2 to

8

13

All

5

5

9 to

15

13

13

5

5

16 to

25

13

13

5

5

26 to

50

13

13

5

5

51 to

90

13

13

7

5

91 to

150

13

13

11

5

151 to

280

13

20

13

5

281 to

500

13

29

16

5

501 to 1,200

13

34

19

20

1,201 to 3,200

50

42

23

20

3,201 to 10,000

50

50

29

20

TABLE VII. Group C inspection.

Method of test

Tests

Requirement

paragraph

paragraph

Capacity T

4.7.11 through 4.7.11.4

Capacity D

4.7.11 through 4.7.11.4

4.6.1.4.1 Sampling plan. A sample, consisting of ns batteries, shall be selected at random from production for each

shipment lot in quantities determined from the formula below, and rounded off in the case of fractions, to an adjacent

integer (up or down for each shipment lot), so that exactly n batteries have been assigned to each capacity test (T and

D), when the sample for the final shipment of the contract lot has been drawn.

NS

(2n)

nS =

N

Where:

ns

=

Total number of sample batteries to be taken from each shipment lot.

Ns

=

Number of batteries in the shipment lot.

N

=

Number of batteries in the contract lot (see table VIII).

n

=

Number of batteries to be taken from the contract lot for each of the two capacity tests, T and D,

in accordance with table VIII (Total number of batteries selected in 2n).

22

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business