MIL-B-49030A

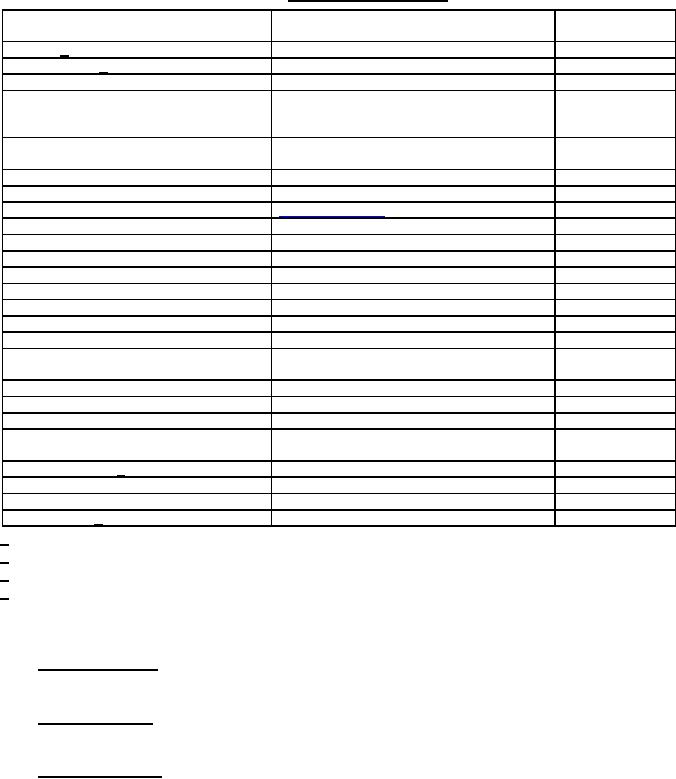

TABLE I. Materials and components.

Materials and components

Applicable specifications or requirements

Methods of test

(see 4.4)

(see 4.4.1)

Solder 1/

Soldering flux 2/

J STD-004, J STD-005 and J STD 006

Metals

Brass

Copper

Beryllium copper

Phosphor bronze

Terneplate

Nickel plating

Wire

Machine screws, studs, and nuts

Plastic, laminated

ASTM D709, type PBE

Plastic, molded

Plastic polyethylene

Webbing, cotton

Tape

Insulating, impregnating, potting, and

sealing compounds

Filler or padding

Cell-block-container material

Intercell separation

Terminals

4.7.4.1.1 and

Jackets, metallic 3/

Jackets, nonmetallic

Terminal mounting plate

Strap handle 4/

1/

For electrical connections, type Sn40 or higher tin content shall be used.

2/

If other fluxes are used, they shall not affect the performance of the battery or reduce its shelf life.

3/

Test method 4.7.2 is applicable only for metallic jackets of material other than terneplate.

4/

Applicable to batteries with metallic jackets only.

3.5.4 Cell-block container. Cell-block container shall be an insulating material surrounding a group or a stack of

individual cells.

3.5.5 Intercell separation. A separator shall be placed between cells in series connected multicell batteries. The

separator shall be an insulating material.

3.5.6 Intercell connections. Intercell connections shall be spot welded in accordance with AWS D17.2/D17.2M,

class B, or soldered depending upon the applicable terminal. Connections between cell blocks and between cell

block and terminal shall be so insulated or positioned as to avoid contact with other conducting material or jacket of

the battery. When insulated wire is soldered to terminal lugs, it shall not be bared more than .094 inch (2.39 mm)

from the lug nor shall it extend more than .094 inch (2.39 mm) beyond the lug.

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business